Truck Air Filter

Truck air filter has an important role in engine system for heavy duty trucks. The intake volume of the truck is higher, and the air absorbed by the engine is also more than air filter car. The air cleaner filter must provide enough clean air for the engine in time when in the road or at the acceleration phase. The truck filters must be high flow air filter.

Truck air filter is to remove the harmful impurities in the air that will enter the cylinder, so as to reduce the early wear of the cylinder, piston, piston ring, valve and valve seat, improving engine durability for heavy duty. The quality air filters hang next to the hood. It will need to add one pre cleaner more before the air filter when work in places with too much dust and smoke for rotary drilling machine etc. The more functions are:

Maintain Maximum Power: A new filter will ensure that the air flowing into the engine is clean. This means that the pure mixture of fuel and air guarantees maximum power, increasing its fuel efficiency. Regular maintenance and replacement of truck air filters will increase the lifetime of your vehicle.

Fully Combust Exhaust Smoke: Protect the airflow thanks to a new filter and avoid excessive amounts of diesel being injected. The best way to avoid black exhaust smoke, the result of incomplete fuel combustion.

Protect Your Engine: Prevent unfiltered particles entering the engine and thereby protect your engine from potential breakdown or damage.

Keep Consumption Low: Limit choke effects and particle detachments by fitting a new filter. Keep the pressure of your engine at the right level; the engine will keep running clean and your sensors will get the right data.

Maintain Extended Service Intervals. Optimal dust-holding capacity allows for more engine uptime between filter changes, so you can keep engines running longer and spend less on filters

Protect Yourself and the Environment: Changing your air filter isn’t just good for you, but it’s also good for the environment. A clean filter means that your truck isn’t putting out contaminants into the air. Air filters block out a large variety of pollutants and allergens that act as a danger to those who breathe them in. Air filters in different environments block airborne irritants and prevent complications resulting from lack of filtration.

The truck air filter with reasonable structure is equipped with PET fiber to reduce noise.

Water stability: the tightly coiled fiber at the top of the filter element also provides additional mechanical properties, helping to prevent degradation of filter protection and gripping wrinkles. Spiral wound technology improves filter stability even when driving in rain.

Structure Features

Many components need to be considered when selecting air cleaner.

1. One of the most important components is the type of gasket: silicone and rubber gasket to ensure the correct sealing in severe conditions.

2. When selecting the air filter, please carefully check the media or paper, embossed pleats and pleated beads to help the filter catch more dirt and last longer. Designed to maximize media surface area. With a larger media surface area, the filter can capture more pollutants while maintaining a low air flow limit for effective engine performance.

3. Another key component of heavy duty air filter is the end cover, which should be designed with consideration of structure and coordination. The heavy duty air cleaner has a metal end cover with a handle, which is easy to install and helps to ensure that the filter is integrated with the housing protecting the engine.

Truck Air Filter Types

Classified by the filtering step:

Primary Filters

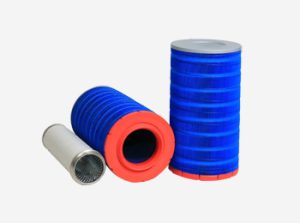

Primary filters, also called main filter, large air filter. The primary filter element is used to remove the impurities in the air flow entering the absorption process, and plays the most important role in air filtration. It can filter particles smaller than Dust Collection Filters.

Secondary Filters

Secondary filters, also called inner filter, smaller air filter, or safety air filter. The secondary filter acts as an available filter and protects the engine when the primary filter is detached from the air filter housing during maintenance, and is usually installed inside the primary filter. Even if the main filter is damaged or replaced, it can also play a protective role. Never operate the engine with only the safety filter. The safety filter is not a backup filter! Compared with the primary filter, the safety filter is more open, less restrictive and less efficient. Secondary filters do not improve the overall efficiency of the air cleaner. The secondary filter protects the engine from potential damage to the main filter – cleaning, incorrect installation, mismatched “fit” or installation of the wrong size filter.

Classified by the structure:

Round Pleating Air filter

Round Pleating Air filter, also called Inertia air filter. There are round primary filter and round safety filter. The pleated paper will be sticked by PU moulding caps or iron end caps.When the air containing dust comes out through the vane ring or swirl tube, there will be vortex (the air of inertia filter enters into the next filter by rotating).

Honeycomb air filter, is a full effect wall flow air filter used for trucks in construction engineering. Honeycomb structure has obvious advantages. The filter paper adopts the groove design, so that the dirty air enters a groove and is discharged through the adjacent grooves. The channel shall be sealed alternately to ensure that the air filter does not leak. The honeycomb air filter intercepts the harmful substances in the air and provides clean air to the engine with minimum airflow resistance, so as to improve the performance and efficiency of the engine and reduce engine wear.The more advantages:

Greatly increased the filtering area, high dirt capacity, and the diaphragm channel is very thin;

Use many honeycomb channels to eliminate harmful gases more thoroughly; they

Perform better in terms of initial limit and dust load capacity.

High machining level, smooth surface and interface, no burr.

Equipped with seals to prevent unfiltered air from entering the engine.

Provide the cleanest air to the engine with the least airflow resistance.

Working Principle

By colliding with and adhering to the dust particles in the air, when the moving particles collide with other objects, the van der Waals forces existing on the surfaces of objects attract each other. This force is not the well-known gravity, magnetic force and electrostatic force, but the force between molecules and molecular groups, which is a kind of micro electrostatic force between the surfaces of two objects.

The air filter media can effectively intercept the dust particles, and at the same time, it does not cause too much resistance to the air flow. In order to achieve good filtration efficiency, the number of fibers in the filter medium should be as much as possible, and in order to reduce the air flow resistance, the fiber material should be as small as possible.

The resistance of air filter increases with the increase of air flow. By increasing the area of filter material, the relative wind speed through the filter material can be reduced to reduce the resistance of the filter. Most of the captured dust is concentrated on the windward side of the filter material. The larger the filter area, the more dust it can hold, the longer the service life of the filter material. The more ash on the filter material, the greater the resistance. When the resistance reaches a certain degree, the life of the air filter will end. Sometimes too much resistance will also make the dust caught on the filter material fly away. In this case, the life of the air filter will also end, and a new air filter needs to be replaced.

In the heavy-duty vehicle, it needs to pass through two air filtration, first safety filtration, the first coarse filtration of large particles, and then the main filter element, which acts as a sieve to catch the small particles in the filter material.

Our Features

High quality honeycomb filter can work for 60, 000km for the trucks. The honeycomb folding increases the filtering area, the honeycomb adopts multi-layer filtering, and the filtering is complete. Provide proven protection for off-road environments and work environments, including construction and agriculture, are notoriously dirty, dusty, and downright filthy.

l Soft rubber for sealing also matches with high quality for polyurethane.

l Plastic frame is first hand and high molecular weight synthetic resin.

l Easty to install. Our filters are perfectly in the place of the normal air filter. You don’t usually need any modification in order to install it. All you need to do is to look for the part number in your old filter and matches it. That makes it possible for you to install it yourself.

l It is easily maintained.

l Save Money. You don’t have to change it very often, spend less on fuel, have a longer lasting engine. You can clean it yourself and not very often

l Safety filter protects engine during primary filter change-outs. Most of truck filters have safety filter inside the primary filter.

l Performance: Matches OEM filter performance in efficiency and dust-holding capacity. Getting to high quality standard in aftermarket air filter.

l Proven Media(famous proven performance media in diesel engines of HV) – Rugged construction holds up in heavy-duty work environments – Dust encapsulation makes servicing easier and cleaner.

The pleating paper is wound around with spiral winding fiber by different width, and the wrinkles are evenly and stably along the total length of the filter. Compared with metal shell, plastic or paper, fiber has lower step resistance, thus reducing pressure drop. This in turn optimizes filtration performance and fuel economy.

Media

Paper air filters are extremely common. These air filters strike a balance between functionality and affordability. Most paper air filters should be replaced between 5000 to 10000 miles. When compared to other models, paper air filters are cheaper and readily available. Unfortunately, the cost of maintaining and replacing paper air filters will increase with time. The upper and end caps can be Iron cap plate or polyurethane material.

Conventional cellulose filter paper, it is also called Wood pulp fiber filter paper. Because of its material is a fiber, so its surface has numerous small holes for the liquid particles through, and the volume of the larger solid particles can not pass. This nature allow the separation of liquid and solid substances mixed together

Cellulous and synthetic, selected the most suitable fiber composition and resin chemistries to meet the specific filter performance requirements. Low restriction and high dust holding capacity make it as ideal filter media and give us the manufacture best performance and price rate. Multiple thickness and stiffness options are available to tailor the composite to your application needs. It also can be used in tractor filters and generator air filters.

Advantages

• improved contaminant separation efficiency

• increased contaminant loading capacity

• low initial and overall airflow restriction

• high temperature performance

• proven performance and durability

Electrospun Ultra-fine nanofiber. It is more suitable to call the fiber with the size of more than 100 nanometers and less than 1 micron as fine fiber or ultra-fine fiber. (1 μM = 1000 nm). These filters are guaranteed to last twice as long as conventional cellulose filters, making them the best choice to reduce maintenance costs and increase uptime for on-highway trucks.

Through electrospinning and other processes, a layer of fine fiber coating is added on the surface of ordinary wood pulp fiber filter paper. The existence of fine fiber coating can greatly reduce the nominal aperture of the filter paper, greatly increase the specific surface area, intercept more fine particles on the surface of the filter paper, and change the filtration mechanism from deep filtration to surface filtration.

At the same time, due to the existence of slip effect, it seems that the fine fiber coating laminated on the surface of wood pulp fiber layer does not increase the air inlet resistance of filter paper, thus achieving a perfect balance between filtration efficiency and pressure drop.

Advantages

1. Greatly improve the filtration efficiency (including initial filtration efficiency and life cycle efficiency), or significantly reduce the amount of dust entering the engine. By attaching a layer of sub–micron fiber with thickness equal to 1 / 300 of human hair to the surface of ordinary filter material, most dust particles in the dirty air can be blocked on the surface of filter material.

2. Increase the maintenance cycle of the filter element several times in the environment dominated by fine particles or carbon smoke.

3. It offers an extremely high dust separation efficiency of up to 99.99% and low press drop, and a long service life. This media is produced by an advanced electro-spinning process.

4. It creates a very fine, continuous, resilient fiber of 0.2–0.3 micron in diameter. This improves particle separation much. At the same time, the flow restriction remains very low.

For example, Under the good road conditions, the diameter of the particles in the air of the traction vehicle is mostly 10 μ m or less, especially the carbon smoke from the exhaust gas of a large number of diesel engines. Nano filter paper, due to its large specific surface area, can accommodate more fine particles and carbon smoke when the same resistance rises.

A truck air filter must be highly efficient at capturing contamination throughout the full life of the filter. This makes structural stability and media strength critically important. Contaminant by-pass (going around, not through the media), failed seals or adhesives and microscopic holes in the media itself will render a filter practically useless. Rigorous testing under extreme conditions for longer than the typical service interval is an excellent indicator of how a filter will perform in its intended application.

Model No. | Tradional | Cellulose | Ahlstrom |

Grammage g/m2 | 138 | 140 | 133 |

Thickness (mm) | 0.46 | 0.5 | 0.48 |

Pemeability CFM(△P=200paL㎡*s) | 420 | 280 | 279 |

Air flow resistance mm/H2O | 22 | 30 | 33±0.0 |

Max Pore μm | 82 | 60 | 58 |

Bursting strength (kpa) | 230 | 240 | 400 |

Resin content (%) | 21 | 22 | 22 |

Volatiles (%) | 5 | 7 | 4±2 |

Stiffness(mn*m) | — | — | 3.2 |

FAQ

Automakers encourage truck owners to inspect the air filter frequently. However, you don’t need to replace it often. Only after specific intervals should the filter be changed. Frequent replacements will be a waste of money. It doesn’t serve the purpose.

If the truck is driven in suburban or clean cities, the air filter will last for at least 20,000 miles. If the truck is driven in dirty conditions, the interval becomes smaller. You may have the replace the filter between 10,000 and 15,000 miles.

There are two sides for each air filter, they are intake port and outlet end.The dirdy air will go from safety air filter to primary air filter for cleaning.

It is dry air filter mostly in the market. You can open your old air filter housing to check or see about the filter cross reference. If it is dry air filter, you don’t need to oil the filter. Usually the original air filters are oiled air filter, you can buy oiled or dry air filter for using, not oiled by yourself!! They are great different for your oiling and manufacturer oiling.

No. Although cabin filter is also called cabin air filter.But the function and media is great different from air filter.

You can check the surface color of the air filter element. If the dust on the surface of the air filter element is removed, the filter paper is still gray black.

Because the common air filter paper has a large filtering aperture, the air passing performance is very large just before 2000 kilometers of replacement. At the same time, the air dust enters the engine and mixes with the engine oil. The cleanliness of the engine oil is reduced. Continue to use to 3000 kilometers, this time common air filter paper aperture is full of dust. It causes the increase of fuel consumption and the decrease of power. So in this process, the driver will feel that the fuel is using more, but the filter can be cleaner. The filter medium of air filter is not the finer the better, nor should it be replaced frequently, but it needs to be durable and durable.