Pre Cleaner

Pre cleaners, we talk about air pre-cleaner mostly in intake system. They are simple devices that remove impurities from the air before it enters into the air filter. The air intake pre cleaners will take out a lot of the heavier, more massive contaminants. Most are centrifugal; they fling particles out to the side. Pre cleaner air filters. Some units collect impurities through the pre cleaner bowl – some of them discharge pollutants directly, but others discharge debris from the exhaust system through the purification system connection.

The pre cleaner will remove approximately 95% of particles 30 microns and larger. The precleaner must locate before the air filter prevents the dust suspended in the air from being sucked into the cylinder and the abrasion of the piston bank and cylinder. Most of them are centrifugal; they throw the particles aside. The installation position is on the top of the engine intake chimney. The other functions are:

1. Reduce downtime and maintenance cost. Air pre-cleaners eject the majority of dust/dirt particles that are heavier than air thus, maintaining engine performance over a longer period.

2. Increase the efficiency of the air intake system. Keep the air filter clean. It protects the intermediate and advanced filters at the back and prolongs the filter life at the back and fewer element changes. Reducing the number of filter element changes reduces the risk of dirt entering the air intake ducts during changes

3. Extend the life of the filter elements. After twice filtration by air pre filter and air filter, almost all particles of dust are kept outside the engine, greatly reducing engine wear and prolonging the service life of the engine and generator

4. Reduce oil consumption and improve generator efficiency.

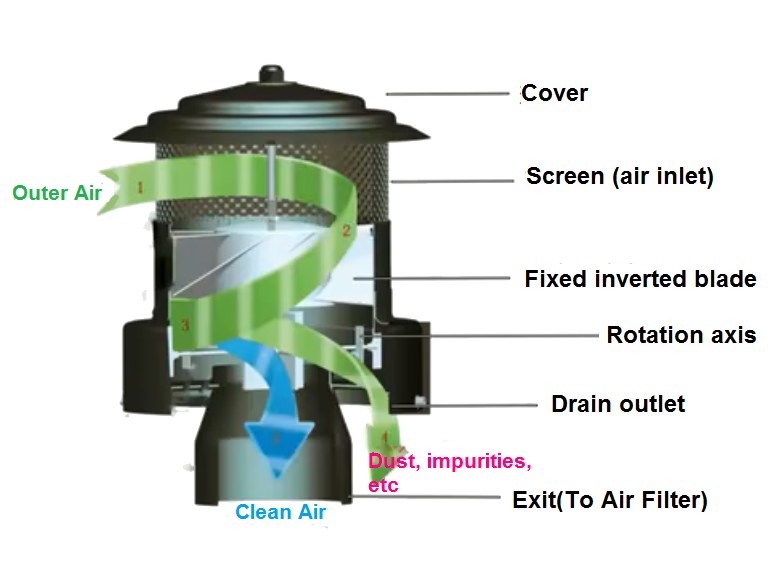

Working Principle

- Air passes through blades fixed at a specific angle and rotateswhen the air enters into the air pre cleaner assembly.

- When the air rotates, the super centrifugal force generated by the special design separates dust, dirt, rain, snow, etc;

- The dust and sundries are driven by the air inlet and quickly rotated by the rotator and blown to the special discharge port;

- Only clean air enters intoair This is the first coarse filter in the air clean system.

Applicatioin

Precleaners are recommended for heavy duty equipments which operate in severe dust conditions, typically in segments such as construction, farming, mining, automotive, deserts and other places with high dust concentration. Air filter car doesn’t need this filter. But truck air filter will need when work in the heavy dust.

Such as CATERPILLAR, KOMATSU, HITACHI, KATO, SUMITOMO, KOBELCO, DAEWOO, HYUNDAI, VOLVO excavators, loaders, rollers, mines, tractors and other construction machinery.

Our Features

l After installation, the cleaning and replacement cycle of filter element is extended by 2-8 times

l Pre cleaners are self-cleaning and require no maintenance.

l Simple installation, zero failure probability.

l Improved products of basin type and swirl type primary filter

l The centrifugal force in the bowl separates up to 75% of the dust before it enters the engine intake system

l Durable, light and non corrosive structure

l Plastic dust pre cleaner bowl allows operators to easily see when maintenance is required

l Keep single bolt maintenance cover for easy maintenance. When the contamination reaches the arrow level, remove the top nut and plastic body and empty – no tools required

l Includes mounting clamp

l There’s no media, just a swirl action with a dust pan someplace. Some are integrated into the housing or filter element itself.

l High impact polymer bowl material for durability.

Pre cleans continually, professional tractor pre cleaner match with tractor air filter to protect the tractor engine is your best choice.

FAQ

Adding air pre filter in the intake system can greatly reduce the dust and impurities entering the air filter, greatly extend the service life of the air filter, and provide strong protection for the engine, improve the engine performance and reduce the maintenance cost.

Except for small models with a capacity of less than 6 tons, most engines have turbochargers, so the overall impact on air intake is negligible; as for the flow problem, the back pressure problem has industry standards.

The air precleaner filters the air entering the engine cylinder for the first time, and the filtered dust and other impurities gather in the duck beak tube. The dust and impurities filtered out by the air precleaner are more, so they must be removed in time.

Pinch the duckbill nozzle to remove the dust and impurities in the pipe. Generally, it should be removed every 3000km or so. If it is driven on a dusty road, it should be removed every two days.