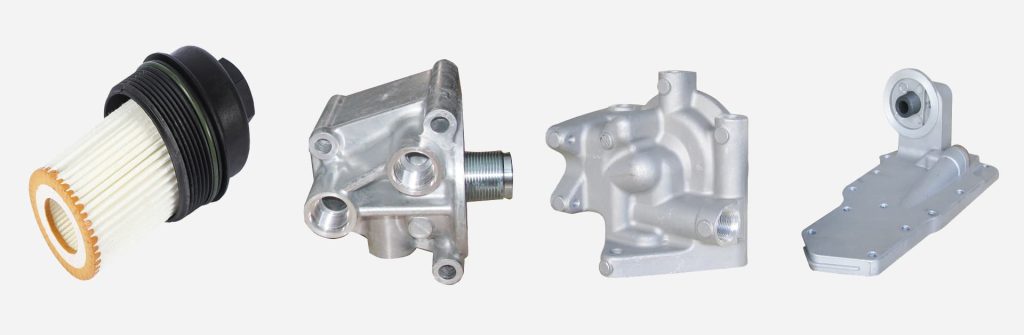

Oil Filter Housing

Almost every engine has an oil filter housing. It is a screwed on part of a canister oil filter or a cartridge oil filter. The whole parts called oil filter assembly. A gasket is required between oil filter and oil filter socket so that the oil filter bracket and filter can be connected seamlessly to prevent engine oil leakage around the base.

Oil filter housing is located in the places that the oil and filter can be changed easily, usually on the top of the engine near the front or on the side of the engine. If the oil filter housing is impacted or otherwise cracked, or the mounting surface is warped, the engine oil will leak and the oil filter socket needs to be replaced. The more function is:

1. Protect and encase the oil filter, protect vulnerable components from contamination issues. Effective engine oil filter bases save both time and money long-term by avoiding unnecessary complications within an engine component.

2. Help cool down the oil that enters the engine. Used for hydraulics, gear oils, diesel fuels, cleaning new oils and coolants, an oil filter bracket is the location where the oil filter sits in a machine. Though sturdy in construction, this base isn’t meant to last forever. Years of use can wear down this base, making it prone to cracks, crags, and breakage.

3. Offer you easy access to your oil filter element. This is important, because oil filter elements require regular replacing. By having a base that offers ready and easy access to the filter element, filter changes should be a breeze!

4. The size of the oil filter base determines the type of filter element that can be used with it. the larger the base, the bigger the filter element it can house. The less the oil pressure drop. Bigger filter elements, generally offer longer filtration services. The thread must match with the filters or the filter can’t install on.

5. Some oil filter bases come with drains. This makes the filtering process easier, while preventing sludge buildup in the base. Other bases come with built-in magnets. These magnets are used to attract metallic particles, thereby helping improve filtration in the assembly.

6. There’s a type of base that comes with a thermal bypass. The thermal bypass enables oil to bypass the filter element when the oil’s temperature is too low or when the filter is too dirty. This enables oil flow even when pressure in the filter element has dipped too low.

7. When using an oil filter base with a bypass valve, you can maximize the life of the filter element by matching the bypass setting to the bypass valve setting. The bypass valve setting is determined by two things: the filter location and the filter material.

Oil filter housing types

Aluminum casting for spin-on screw filter and bypass oil filter

Plastic case for cartridge oil filter

Our Features

We have multiple oil filter base models available that fit a variety of dimensions, flow rates, and base capacities. The heads are an integral part of ensuring your critical equipment receives the cleanest possible fuel and oil. It must be used to Combine with the proper Clean Solutions filters.

l Safe and environmental protection, strong and durable

l Strict craft, save time and energy

l Long term use of no rust, comfortable handle

l Easy fixed and connected load

l Temperature stability can prolongs product life and ensures good performance

l Low friction ensures high efficiency and long life

l Simple and reliable structure design.

l Aluminum head with steel inserts to minimize metal-to-metal bonding or galling between the head and filter

l Fluorocarbon seals are compatible with most fluids

l Pre-ported for optional pressure gauges or service indicators

Filter heads can be mounted in any attitude, but we suggest when choosing an oil filter that is to be fitted in other than an upright, filter below, position, it should have an anti-drain valve. No provision is made in our heads for filter relief valves, these are available built-in on some filter elements, they should be avoided if regular oil changing and gentle warm ups can be relied upon.

Media

1. Plastic macromolecules. A strong, one-piece can design and a non-metallic center tube that is cleaner and stronger than metal, Fuel Filters maximize cleanliness and minimize potential leaks.

2. Aluminum casting housing. Compared with other metal materials, aluminum housing has small density and light weight. Its chemical properties are stable, non-magnetic and can be recycled. It is a kind of benign and recyclable metal material. More advantages are:

l The aluminum shell is treated by two processes, hot and cold. It has good casting performance and strong corrosion resistance.

l The surface treatment performance of aluminum shell is good, the elasticity coefficient of aluminum shell is small, collision and friction can not spark, and it is the best in automobile technology.

l Aluminum shell has no metal pollution, no toxicity and no volatile metal in surface oxide layer.

l Aluminum shell has strong plasticity and good productivity, which has a good advantage for production.

FAQ

It is far better to get a specific tool to remove the filter (such as rubber filter wrench or chain filter wrench), or in a pinch, a large pair of slip-jaw pliers, since they will offer better leverage and work on a crushed filter. Note that oil filters have specific tightening instructions in each filter’s body printing, if followed this problem will not occur.

It is a aluminum material. Some paints into black color. It is a bracket for installing oil spin-on filters.

Step 1: Determine the cause of the oil leakage. If the shell is broken, it needs to be replaced. Sometimes the oil filter gasket will be the cause. You can change the gasket first to check the right reason of leakage before changing the housing.

Step 2: Removing oil filter

Step 3: Drain engine oil

Step 4: Loosen the oil filter housing from its installation position and install a new one in its original position

Step 5: Fill the engine oil, replace the filter and run the engine to confirm that the leak has been repaired