Fuel Water Separator

A fuel water separator is a small primary filtration used to remove the water from the diesel before it reaches to the sensitive parts of the engine. Water and contaminants have a direct impact on the service life and performance of diesel engines.

Diesel fuel filter water separator kits are an important preventative measure for the protection of fuel injectors, especially common rail diesel systems, which are incredibly efficient but intolerant to water and contaminants. The diesel systems require extremely fine levels of filtration due to super tight clearances in pumps and injectors. The separator is usually installed on the engine skid on a suitable bracket next to the engine. The more function is:

First line of defence filtering water and particulates from diesel before it gets to the fine fuel filtration.

fuel water separator Prevent expensive repair and maintenance costs of diesel fuel systems.

Fuel water separator Reduce the impact of water that has entered the fuel supply via seepage in storage tanks or condensation build up.

Fuel water separator Provide additional ‘pre-fuel’ filter protection for the standard fuel filter in diesel delivery systems.

Fuel water separator can avoid blockage or abrasive damage that can severely impact performance. Reduce oil consumption

Efficient separation of the oil which escapes from the crankcase breather system, filtering of aerosols

Fuel water separator prevent accelerated deterioration of the oil due to oxidation and silting

Relief of the engine sealing system

Fuel water separator aid adherence to strict emission standards

The fuel filter water separator improves the filtration performance and prolongs the service life of the main fuel filter. It can prevent the pump from being damaged in the previous delivery process, such as wear or corrosion caused by water in fuel.

Fuel water separator Types

Fuel water separator also called prefilter. There are two filters in some heavy equipment, prefilter and fuel filter. In boat fuel filter water separator and marine fuel filter water separator kit have double-way filtration and has the function of coarse filtration. The fuel prefilter separates 30% of the very fine particles, 6 micron size and more than 93% of the water (in accordance with ISO4020).

SWK2000 Series 300-600FG

Single and double pre–filter for separation of both emulsified and free water from diesel for boat, marine and construction (off-highway). With the duplex version, you can switch boat fuel water separator during operation. You can also drain the filter if it is clogged and you do not have a spare element available.

Capacities: 5-260 liters / min.

Various options like water alarm, water sensors (probes) and different micron.

Pro series FH SERIES

Prefilter for separation of both emulsified and free water from diesel for construction (off-highway) and transport. (Own series for classed ships.) Due to the transparent filter bowl, you can easily see when the filter needs to be replaced.

Capacities: 11.3 – 19 liters / min.

Various options with water alarms, heaters and purity requirements.

Spin-on diesel filter with Open Port for Bowl

Filters with an open port for a water collection bowl

Fuel manager series

These filters remove excess water from your fuel source and have valves for convenient draining of this water.

Water separator Series

Water separator with fuel strainer inside

Fuel fitler base+fuel strainer+filter bowl

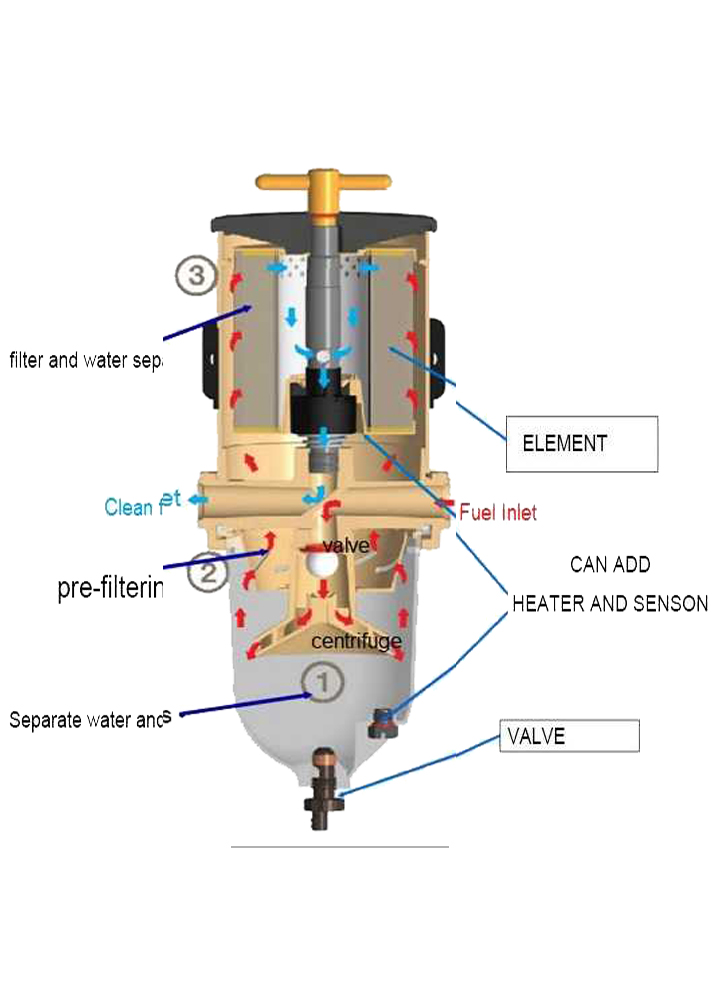

Filtering Steps

All fuel must pass through both the additional diesel fuel water separator kit and fuel filter before reaching components such as high-pressure fuel pumps and injectors.

1. As fuel enters, it moves past the internal check valve, then through the turbine centrifuge where it flows in a spiraling direction, spiming off large particulates and water droplets, which is being heavier than fuel, the large particulates and water droplets fall to the bottom of the bowl.

2. Smaller water droplets bead-up along. After filtering by the replacement filter, small water and particulates will be on the surface of the filter. When large enough, they also fall into the high-capacity bowl to be drained as needed

3. Clean fuel will exit outlet. Water, asphaltenes, algae, rust, and tiny solids from fuel will be removed.

Assebly Components

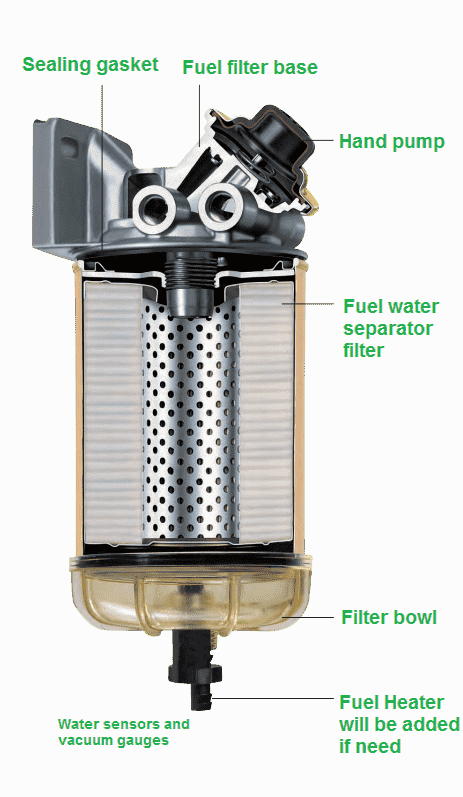

- Fuel water separator filter uses a folded corrugated paper element to turn the water particles into sufficiently large droplets that will fall into a water cup at the bottom of the filter by gravity.

- At the time of delivery, in order to facilitate installation, the filter element is not firmly placed on the filter head. An optimized sealing gasket is also provided to reduce the tightening and loosening.

- Filter bowl is made of nylon or aluminum treated with silicone, without rust or corrosion, which plays a role of safety device and waterproof, and prevents small particles of the first stage water from entering the engine. They do not change color due to exposure to alcohol, additives or UV light. The driver of the vehicle can visually check the water accumulation and drain it as required.

- The integral fuel heater allows you to work normally in cold weather.

- Water sensors and vacuum gauges for signal services are valuable options for most models. A semi-active water sensor can be installed to check the water level in the water tank and resist the temperature between – 30 and + 110 ℃.

- Fuel filter base, connectand fix the fuel filter cartridge or spin on filter to the vehicle. Multi port, easy to install, add options.

- The durable hand pump is installed in the filter

Tips: To remove the water from the diesel water separator, the operator should periodically check the fuel water separator and open the drain valve to drain the water. All fuel/water separators are designed to be installed in line with the appropriate filter housing.

Our Features

l Maximum flow rate: 150 lph / 40 gph

l Operating pressure: 690 KPA / 0-100 psi without bowl

l B20 compatible – a wide range of fuel compatibility, including bio-diesel up to B20, allows for use with most modern fuel chemistries

l Twist&Drain valves minimize components – provides flexible options that make routine maintenance clean, easy, and efficient.

l Add-on water collection bowl available for easy water inspection

l Manufactured in our own facilities, we control the quality of the parts you need to keep your equipment performing at optimum levels.

l The inside fuel filter elements are metal-free and can be incinerated without leaving any residue.

Application

l Heavy-duty, on-highway transportation

l Commercial trucks and buses

l Agriculture

l Power generation

l Payloaders

l Lift trucks/Marine

l Mining

l Oil and gas

l Construction

l Automotive

l Generators

FAQ

Principle is Centrifugal Force to eliminate heavy particles (Water and Dirt). The followsing factors that we also need to consider:

1.Size – Compact in equivalent flow rate model

2.Range – as wide range of models according to Flow rate and Application

3.Price – The right price with performance filtration.

4.Integration – Easy to install. have additionally Water Sensors, Heating Coil if application require, have duplex models.

5.Efficiency – Claims almost 100% filtration efficiency

Besides being abrasive to engine components and cylinder walls, water and contamination displaces diesel fuel’s lubricative coating on the high precision injector components, causing tolerance erosion, surface pitting, fuel pressure loss and poor performance. Unfortunately, there is no way to completely prevent water from contaminating fuel. Condensation is constantly forming inside fuel tanks.

The standard configuration of fuel water separator is 30 microns, which is sufficient for most applications. Any collected water falls through the center of the element, and fuel flows out of the filter to the outlet. Any accumulated water or other impurities can be discharged through the drain valve at the bottom of the water collection bowl. Unfortunately, there is no way to completely prevent water from polluting fuel. Damage can be catastrophic and expensive, so the best defense is to add auxiliary filters to clean the fuel better and more thoroughly, and replace them regularly

If the separator fails, any water in the fuel can wear away lubricants on the diesel fuel injectors. When the device removes contaminants and solid materials, it helps prevent engine clogging.

According to the quality of fuel, it’s better to change after 8000-10000km. You can check the bowl when it is full of water, open the drain valve to drain the water on time usually.

1.The fuel enters the fuel water separator (i.e. the oil inlet side of the fuel water separator in) first from the daily fuel tank or the base fuel tank. The fuel flow impulses the rubber impeller of the fuel water separator to rotate, which makes the water settle to the bottom of the separator. Because the specific gravity of the water is heavier than the fuel, the water will settle at the bottom. At the same time, there is a red rubber ring at the bottom of the separator. When there is water at the bottom of the separator, it will sink when it is wet, the rubber will float.

2.When the fuel is filled with the fuel oil separator, the fuel is filtered by the filter element and then soaked into the inner side of the inner core. There is an iron pipe in the middle of the inner side of the inner core, and there are two holes in the iron pipe. The fuel flows to the unit’s oil delivery pump (i.e. the oil outlet side of the fuel water separator) through the iron pipe hole. The out of the water separator is output to the unit hand oil pump.

3.The fuel water separator is marked with in inlet and out outlet. Before starting the unit, the joint of fuel water separator and oil pipe must be connected firmly without looseness and air leakage, and check whether the oil inlet to water separator and oil pipe output to the unit are connected wrongly. Then fill the filter separatorwith fuel to pump and empty the unit manually.