Hydraulic Filter Housing

The hydraulic filter housing is designed to be added to the hydraulic system in a kidney circuit configuration. It needs to be customized according to the requirements of hydraulic system environment and hydraulic filter. It helps the metabolism of machines and equipment.

Spin-on hydraulic filter housing supports all components and is designed with multiple damping devices, which has good damping effect, can make the hydraulic filter have a stable working environment and good sealing performance. More functions are:

1. Prevent oil leakage and bypass of unfiltered hydraulic oil and pollutants. The shell is made of high quality rubber material and structure, which can completely separate the filter from the outside.

2. Protect the hydraulic components from these leaks and help to ensure the service life and function of the components, especially the internal filter media. Reduce machine and system downtime.

3. Reduce maintenance cost. Compare the filter fee with the engine fee, and you will see a big difference. And the shell is hard to break, usually we only need to replace the filter element or other parts inside.

4. The design is easy to clean and has little obstruction to medium flow.

5. Suitable shell components help the filter element to play its maximum role, so as to achieve high-quality hydraulic filtration process

6. Bear more pressure and temperature than the internal filter element.

7. Help effectively remove pollutants and other unnecessary particles. The enclosure is an essential accessory. It also filters out larger particles.

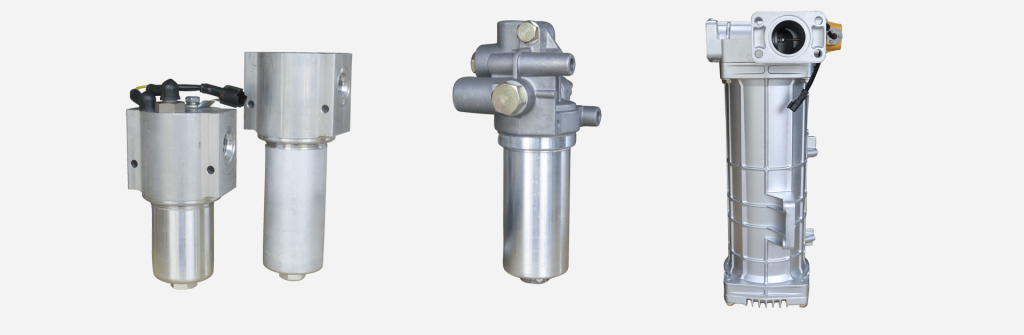

Hydraulic Filter Housing Types

We offer a selection of quality hydraulic oil filter housings in a variety of sizes that protect important components. Pressure filters range from low-pressure standard filter housings to sturdy filter housings (eg extremely high pressures of 750-1200 bar). Our hydraulic filter housings will also be continuously upgraded according to different pressures. Most of these filters are contained in plastic, steel, or aluminum housings. The type of housing primarily depends on the pressure levels involved.

Low pressure hydraulic filter housing, The pressure up to 10 bars for Tank-mounted filter housings and low-pressure return line filters. It would be plastic or aluminum housings.

Medium pressure filter housing, Return line filter housing mostly. The oil return line hydraulic filter housing cleans the oil after passing through the working hydraulic circuit to ensure that all particles generated during use of the oil are removed before returning to the oil.

High pressure hydralic filter housing, finely filters the hydraulic oil under high operating pressure, removing all contaminants at 25, 10, and 5 micron absolute values (based on the type of housing and component used). Such as transmission filter is install inside.

Our Features

As a hydraulic filter supplier, we guarantee reliable performance and service life of components, systems and machinery. We offer the best performance features, such as:

l O-rings are used to provide a reliable seal. O ring material (Ding Jing rubber, fluorocarbon elastomer and ethylene propylene rubber NPT, BSPP, SAE) can be selected for compatibility with petroleum, synthetic liquid, water glycol, oil / water emulsion and high water base liquid.

l The poppet type bypass valve at the head of the filter provides positive seal during normal operation and quick opening during cold start and flow fluctuation. (optional non bypass)

l All enclosures are integrity tested and conform to ASME and ISO 9001

l The fatigue pressure rating is equal to the maximum allowable working pressure rating.

l Non welded shell design reduces stress concentration and prevents fatigue failure.

l High β stability in a wide range of pressure difference

l High pressure stability, low pressure drop

l High pollution retention and long service life

l Wide selection of filter grade, best filter material for specific application

l Wide range of models and Applications

l Housing assembly with economic alternatives

FAQ

The condition of the operating fluid plays a key role in this objective, since approximately 70% of all breakdowns of hydraulic and lubrication systems can be attributed to the condition of the oil – with proven detrimental effects on the efficiency and profitability of systems and equipment. Filter housing can enhance the protection of your operating fluid, thus improving the quality of your system as a whole.

Selecting the optimum filtration solution contributes significantly to preventing damage caused by contamination, to increasing the availability of the system and therefore to increasing productivity considerably.